In the fast-paced goods turnover environment of warehousing and logistics, efficient warehouse lighting plays a crucial role in improving operational efficiency and reducing energy costs. Under the national "Dual Carbon Strategy" and the actual energy-saving demands of enterprise, how to balance the sufficiency and energy efficiency of lighting has become a question that every warehouse manager needs to consider.

Shanghai Shufeng Logistics Technology Group Co., Ltd. (referred to as "Shufeng Logistics"), as a leading provider of warehousing and distribution services for FMCG in China, has fully considered the lighting and energy efficiency needs of its clients. It has implemented an intelligent lighting system solution in warehouse management, achieving intelligent regulation such as lights turning on when people enter and off when they leave. This has enabled energy savings for over 50% in a 18,000-square-meter warehouse area. After full deployment, it is expected to save over 50,000 kilowatt-hours of electricity annually, equivalent to reducing carbon dioxide emissions by over 50 tons.

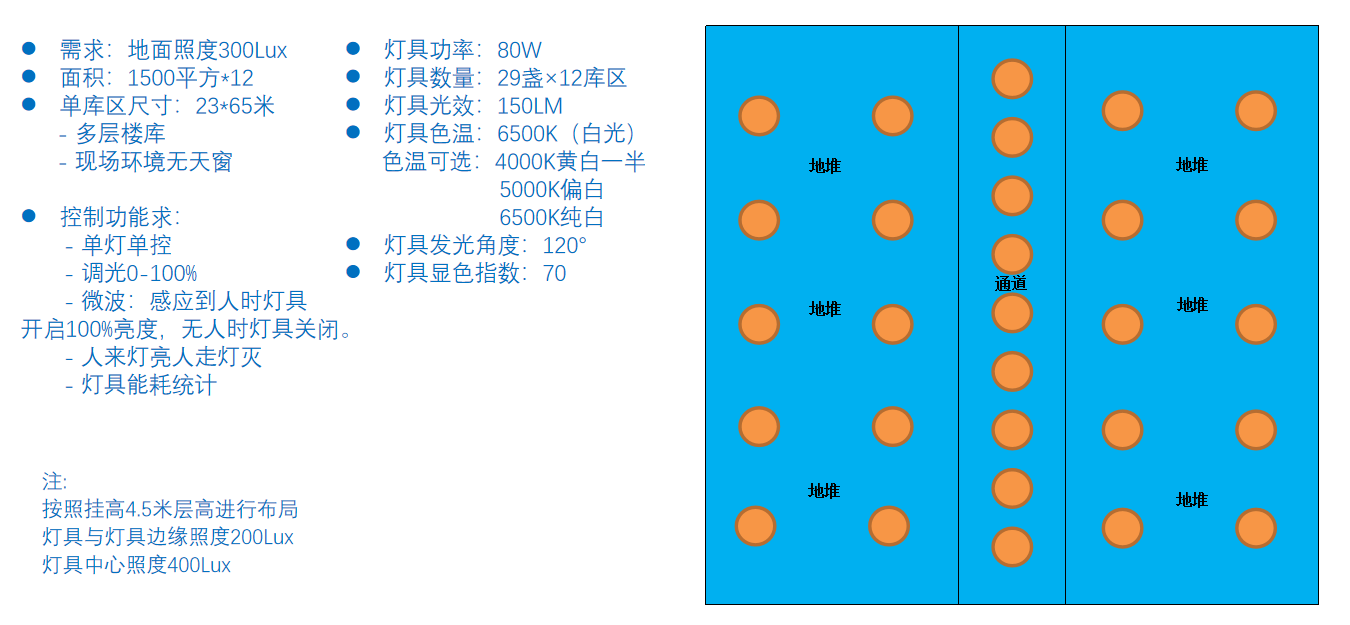

1. Layout of Intelligent Lighting System

FMCG warehousing management is characterized by high SKUs, high turnover, and high frequency. Due to the high stacking of goods and the fast speed of inbound and outbound operations, the lighting environment in the warehouse plays a crucial role in the safety and efficiency of forklift operations.

The lighting system in the Shufeng Logistics warehouse fully takes into account the following factors:

Space size: The overall size of the warehouse significantly influences the design of the lighting scheme. Larger areas require powerful industrial and mining lighting options, and warehouses with high ceilings need high-bay lighting solutions that can effectively distribute light to ensure comprehensive and uniform illumination.

Lighting energy efficiency: There are various lighting fixture options to choose from, each with its unique advantages. LED lighting, fluorescent lamps, and high-intensity discharge (HID) lamps are common choices. LED technology is increasingly becoming the ideal option due to its energy efficiency and versatility in various applications.

Lighting layout: The placement of shelves will create shadows and dark areas, so lighting in these areas is of vital importance. The lamps can be placed in the aisles between the shelves or at both ends of the shelves to ensure that the shadow areas are eliminated.

In this case , the warehouse height is 4.5 meters, and the lighting area is approximately 1,500 square meters ×12 warehouse areas. Therefore, 29×12 80W lamps were arranged, with a luminous efficacy of 150LM, which can effectively eliminate the shadow area in the stacking area.

2.Illumination intensity and uniformity

Comply with national standards: Generally speaking, the lighting intensity of large warehouses should reach 200-300 Lux, while that of small warehouses can be controlled at 150-200 Lux. In some special working areas, such as loading and unloading areas or quality inspection areas, the lighting intensity requirement can be higher, reaching 300-500 Lux, to ensure the work efficiency and safety of employees.

Lighting uniformity standard: The lighting system should be designed to ensure uniform light distribution and the reasonable installation positions of the lamps, reducing shadows and blind spots, so as to achieve uniform lighting coverage and improve work efficiency and safety. In addition, depending on the special circumstances of the warehouse, the lighting intensity can be appropriately increased for detailed operation areas such as package modification to ensure the accuracy and safety of the operators.

3.Intelligent Energy Efficiency Management and Control

The intelligent lighting system, by integrating sensors and lighting control modules, realizes the automatic management of lighting equipment and has become a key solution for energy conservation and consumption reduction.

Based on the principle that the lights are on when people come and off when they leave, the lighting groups equipped with microwave sensors can achieve adaptive dimming of the environment, remote control, scheduled tasks and multi-device linkage.They can dynamically adjust the brightness according to people‘s activities and natural light, avoid unnecessary energy consumption, and thus achieve the purpose of saving energy and extending the service life of lighting equipment.

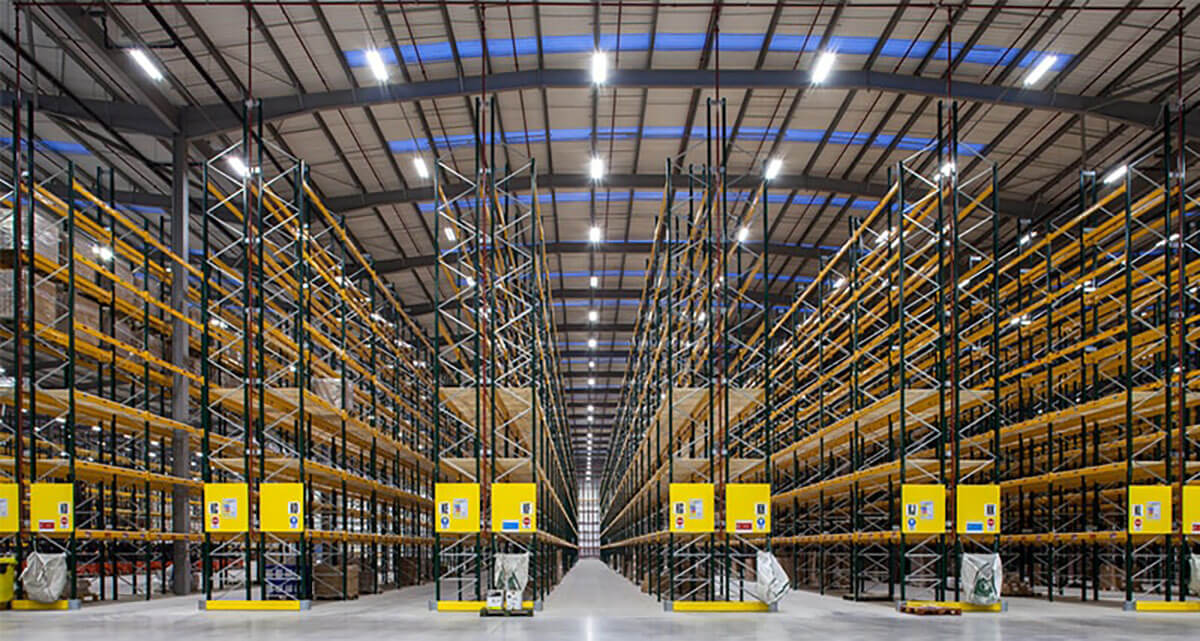

effect picture

The intelligent lighting system represents the next evolutionary stage of warehouse lighting. Shufeng Logistics fully leverage the power of the Internet of Things, working hand in hand with customers to drive the entire value chain to reduce carbon emissions, and jointly create more high-quality and environmentally friendly intelligent lighting system solutions, making due contributions to national goals of "carbon neutrality" and "carbon peak".

Author: Shufeng Logistcs Tech Dept